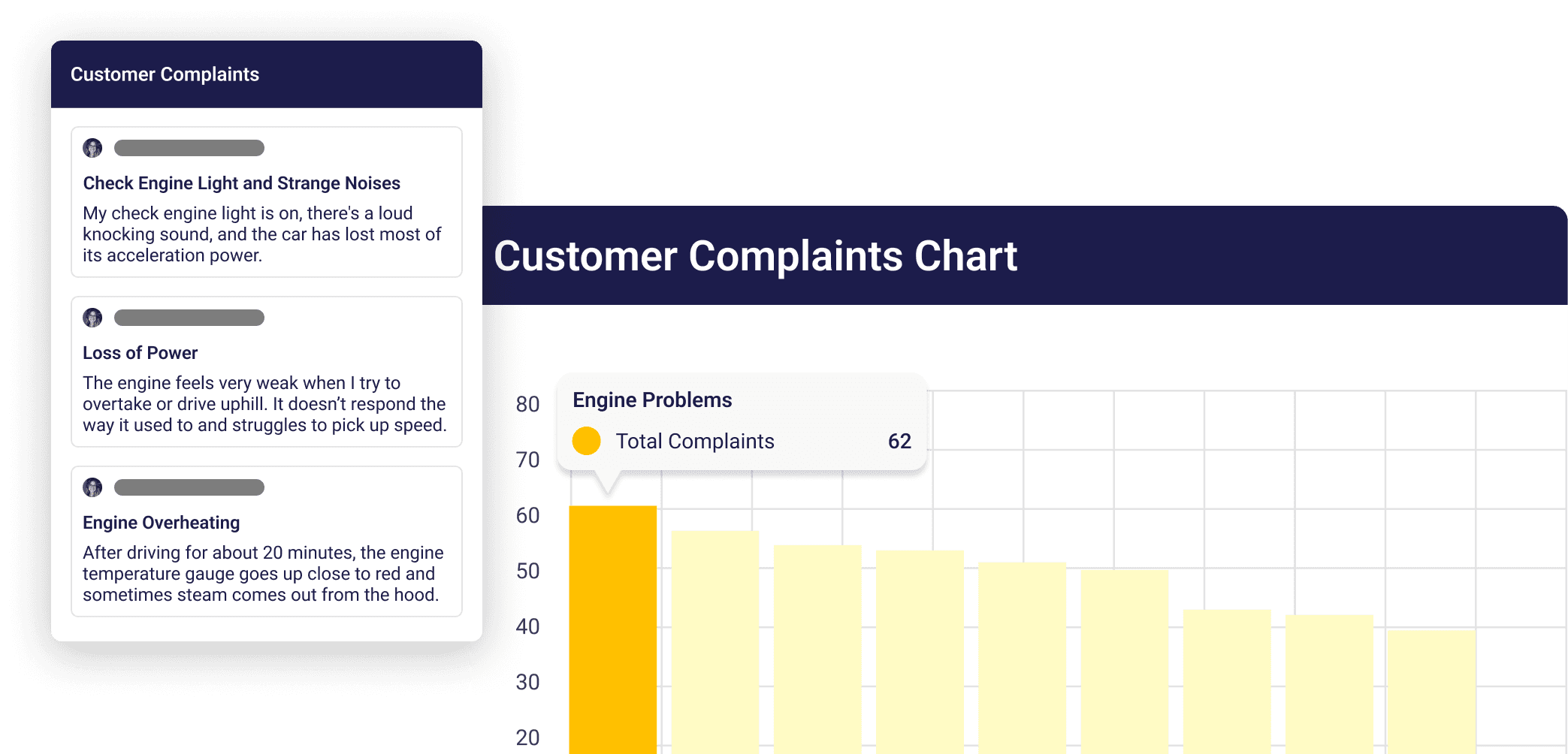

The spreadsheet chaos

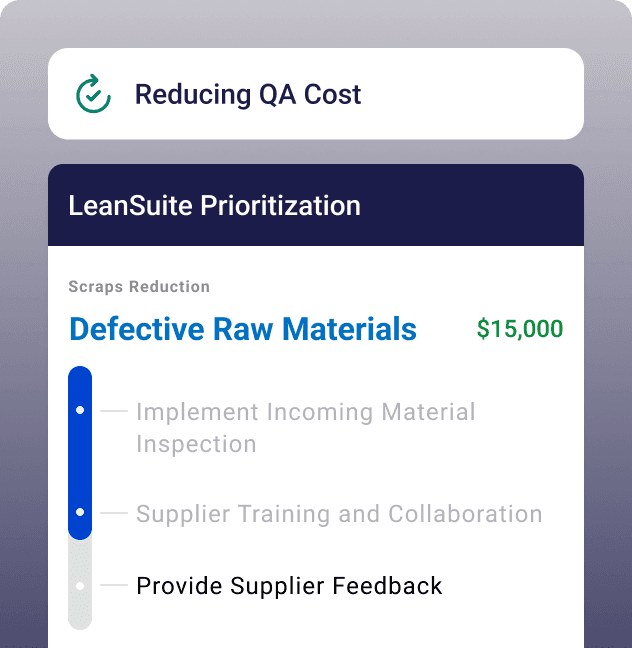

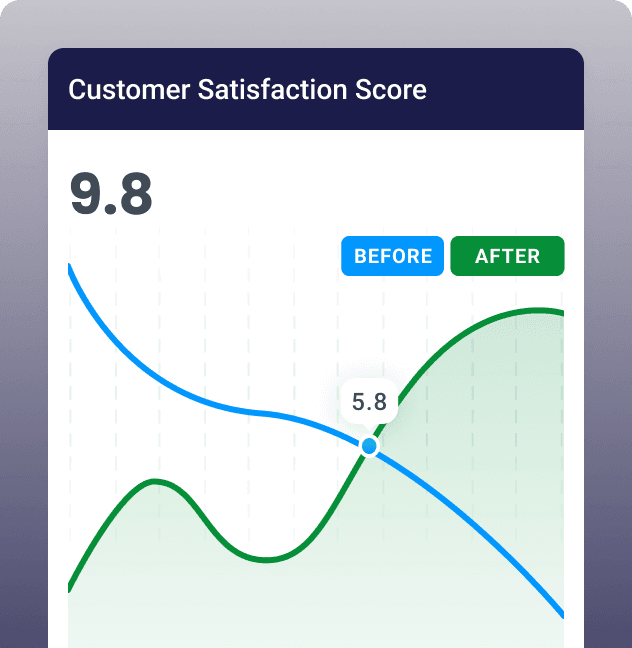

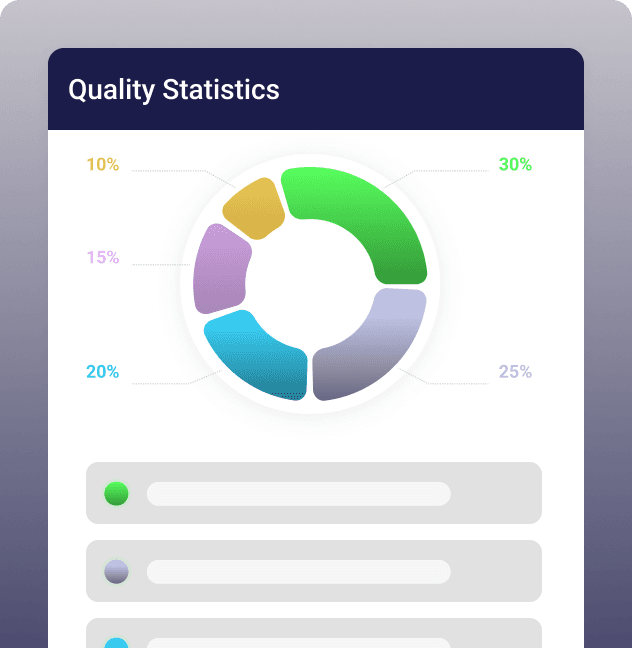

Your team is busy, but are they busy with the right things? Managing a long list of quality issues in spreadsheets leads to "squeaky wheel" prioritization, wasted resources on low- impact projects, and difficulty proving the ROI of your quality improvements.