The paper trail problem

Relying on paper leads to inconsistent execution, zero real-time visibility, and preventable downtime when small, un-caught issues snowball into major breakdowns.

Capture, standardize, and replicate your most effective operational practices across your entire organization.

By clicking "Schedule Demo," you agree to the use of your data in accordance with LeanSuite's Privacy Notice, including for marketing purposes.

Relying on paper leads to inconsistent execution, zero real-time visibility, and preventable downtime when small, un-caught issues snowball into major breakdowns.

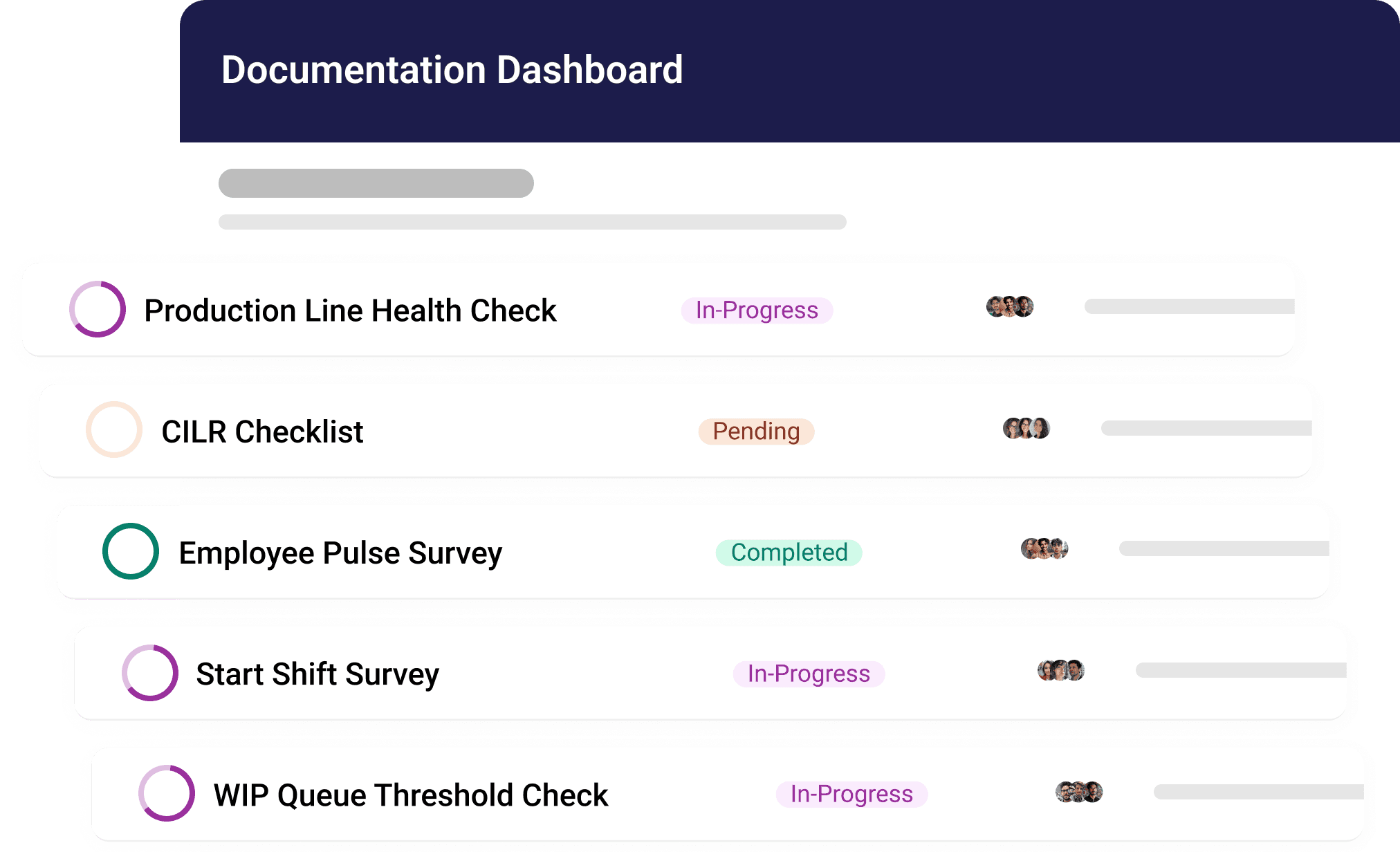

LeanSuite transforms daily equipment care into a dynamic part of your operator's standard work, providing instant visibility and empowering your team to catch problems at the source.

LeanSuite provides a structured framework that guides your best ideas from concept to measured results.

Capture best practices as they happen. Document project wins and Kaizen events by attaching relevant photos, videos, and data for a complete, detailed record.

Formalize captured practices into clear, step-by-step standards. Use the streamlined approval workflow to vet, refine, and approve new procedures for guaranteed quality.

Instantly push approved standards to all relevant sites with a single click. Teams are notified and the new procedure is immediately added to their workflow.

Track rollout success on a live dashboard. Monitor site adoption and training completion, then measure the operational and financial impact to demonstrate ROI.