Improve compliance and audit-readiness

Create an “alway-on” audit trail. Stop the fire drills and walk into any internal or external audit with a complete, time-stamped, and verifiable record of every check and corrective action.

Build, schedule, and act on any type of shop floor audit or inspection, turning your compliance tasks into a powerful engine for continuous improvement.

By clicking "Schedule Demo," you agree to the use of your data in accordance with LeanSuite's Privacy Notice, including for marketing purposes.

Go beyond better checklists. Our system transforms your entire approach to compliance, accountability, and continuous improvement.

Create an “alway-on” audit trail. Stop the fire drills and walk into any internal or external audit with a complete, time-stamped, and verifiable record of every check and corrective action.

Turn findings into fuel for your CI engine. Our seamless workflow ensures every non-conformance becomes a tracked, accountable action item, driving down recurring problems.

Get a live, plant-wide view of your entire audit program. See who is completing their checks on time and who isn't, creating a culture of ownership and accountability.

LeanSuite provides a structured framework that guides your best ideas from concept to measured results.

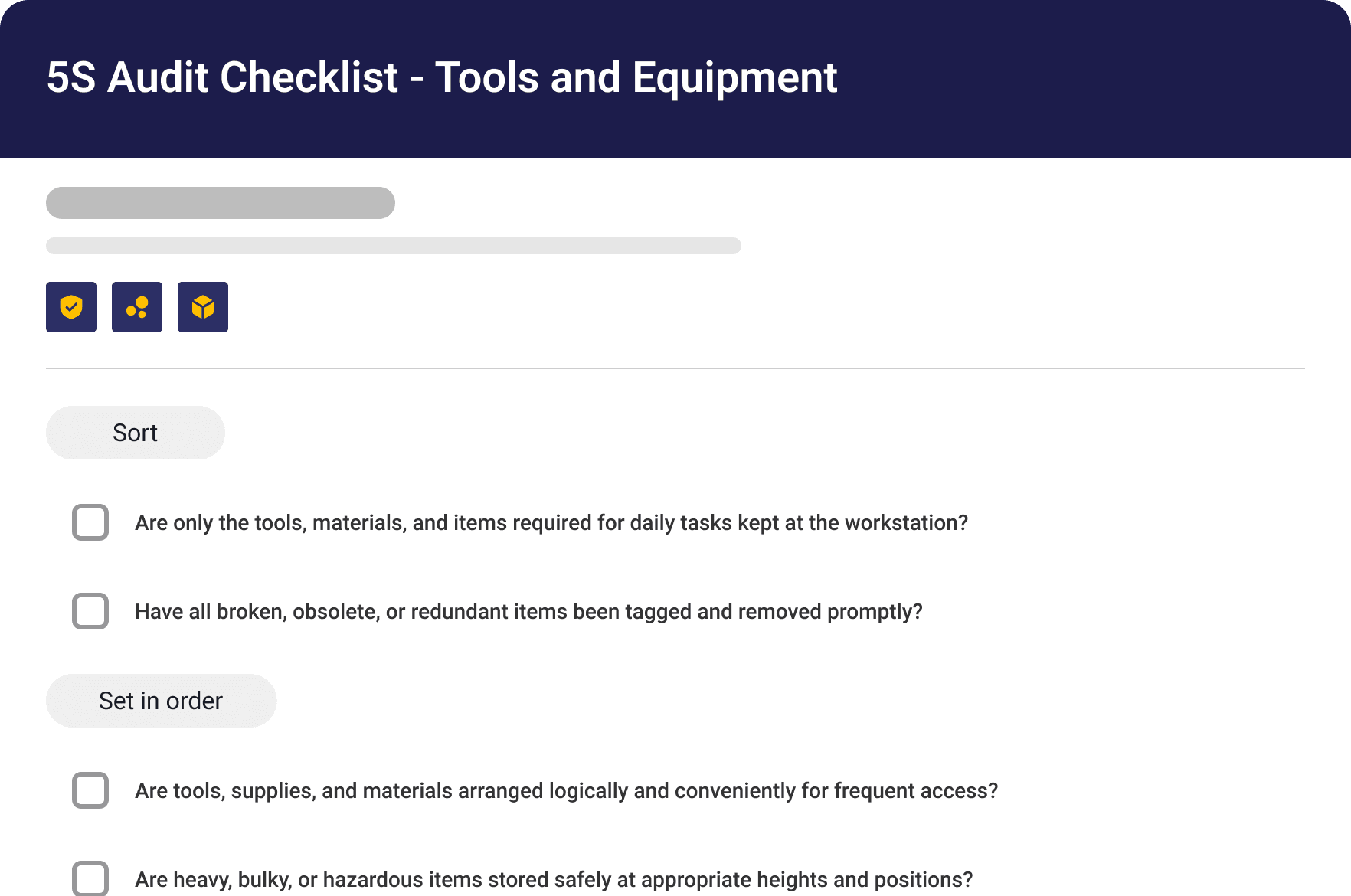

Use our flexible Lean Creator to build any checklist you need, from a simple Gemba walk audit to a complex layered process audit. Then, schedule it to be automatically assigned to the right people at the right frequency.

Auditors can easily complete their checks on any tablet or mobile device, capturing photos and comments as evidence directly from the shop floor. Our offline mode ensures that the work gets done even in areas with poor Wi-Fi.

Get a live, plant-wide dashboard showing your audit completion rates in real time. A visual heat map instantly shows you where non-conformances are clustering, allowing you to spot systemic problems at a glance.

This is where compliance becomes improvement. Any non-conformance identified during an audit is not just a finding; it's the starting point for a solution. With a single click, you can:

Launch a formal Kaizen project

Create an issue tag for maintenance or support team

Assign a simple corrective action plan

LeanSuite's Lean Creator is more than just an audit tool; it's a platform for standardizing any recurring check on your shop floor.

Layered Process Audits (LPAs), In-Process Quality Checks, Final Inspection Checklists.

Safety Walks, Lockout/Tagout (LOTO) Audits, PPE Compliance Checks, Fire Extinguisher Inspections.

5S Audits, Gemba Walks, Standard Work Audits, Kaizen Newspaper Tracking.

Preventive Maintenance (PM) Checks, Autonomous Maintenance Handover Audits.